ITEM SPECIFICS

-

Brand

worildia

-

origin

Republic of Korea

-

Size(Capacity)

NA

-

Material

PCBN+TiC/TiN/TiCN/AIN Bond +WC-co substrate

-

Features

Specialized in machining hardened automotive components such as gear, bearings, axle parts

-

Expiry Date

30~90 minutes

PRODUCT DESCRIPTION

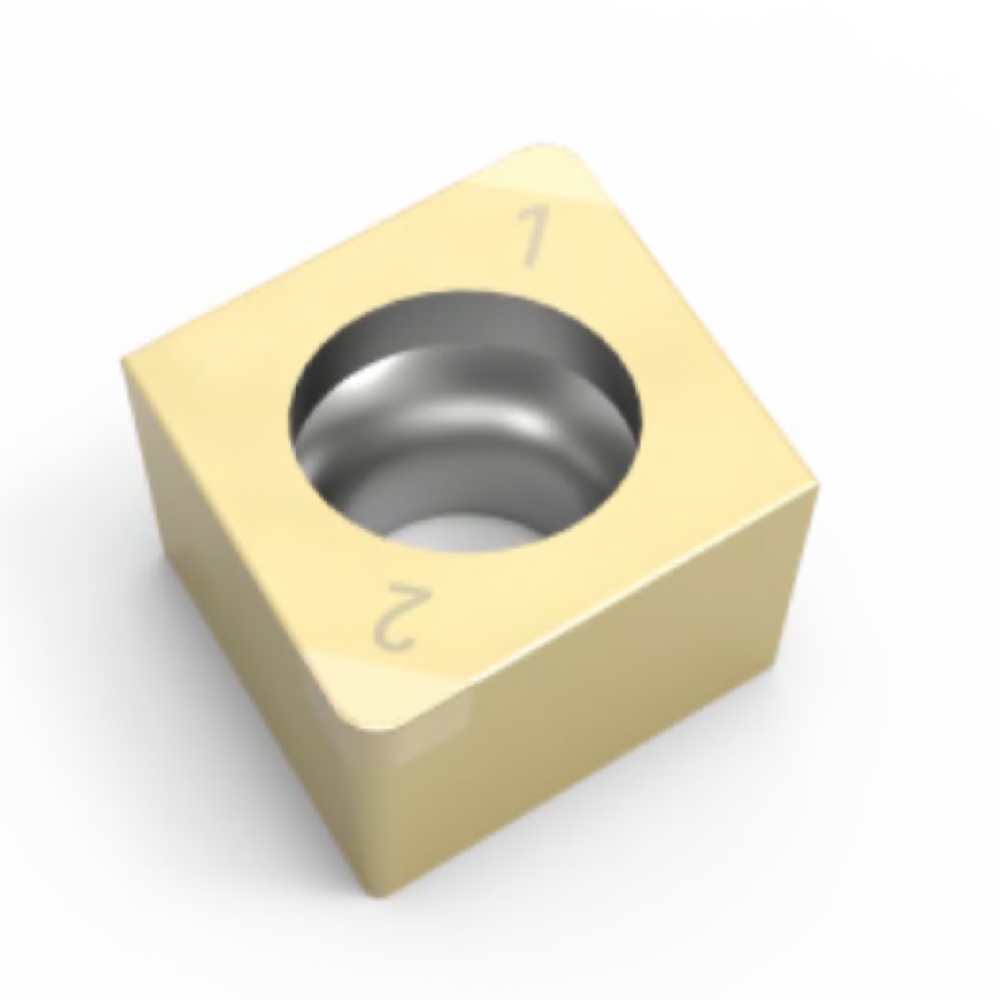

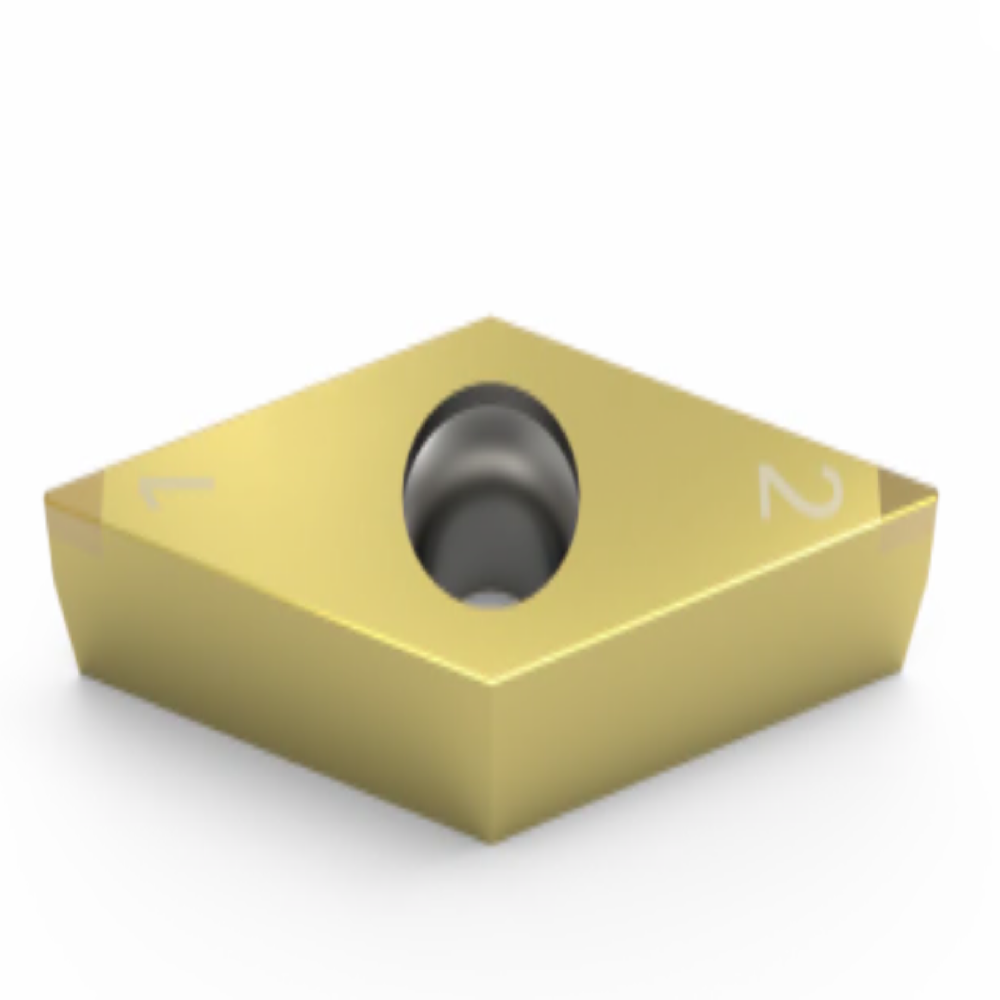

Coated CBN Inserts are engineered for high-performance machining of hardened steels, cast irons, and powder metallurgy materials.

The inserts feature a polycrystalline cubic boron nitride (PCBN) cutting x-layer — a composite of CBN particles bonded with TiC, TiN, TiCN, or AlN ceramic binders — firmly brazed onto a WC–Co carbide substrate for superior structural integrity.

The inserts feature a polycrystalline cubic boron nitride (PCBN) cutting x-layer — a composite of CBN particles bonded with TiC, TiN, TiCN, or AlN ceramic binders — firmly brazed onto a WC–Co carbide substrate for superior structural integrity.

Enhanced with advanced PVD coatings (C2, CE series), these inserts deliver outstanding wear resistance, thermal stability, and edge toughness, extending tool life by 50–100% compared with conventional CBN inserts.

Their optimized edge geometry and chip-breaking design enable efficient continuous and interrupted cutting, while maintaining excellent surface finish and dimensional accuracy.

Designed for precision machining in the automotive, bearing, and mold industries, WORLDIA PCBN inserts provide a reliable solution for achieving long tool life, stable performance, and reduced machining cost under demanding cutting conditions.

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Telegraphic Transfer : T/T

- Name : Yu Byung il

SHIPPING

Shipping from :

Republic of Korea

- 39-20 Hwangdong 3-gil, Naju-si, Jeollanam-do (58327)

KBM corporation

The person in charge

Byung il YuAddress

39-20 Hwangdong 3-gil, Naju-si, Jeollanam-do (58327)

Introduction

KBM supplies raw materials and non-ferrous metal products such as tungsten, molybdenum, and cobalt to Korea, Japan, China, and more than 40 countries around the world.

Our products are used across a wide range of industries, including cutting tools, automobiles, semiconductors, and steel. We are also diversifying our business into non-ferrous metal material manufacturing, pneumatic equipment, and cutting tool sectors.

Valuing trust with our customers as our most important asset, KBM is committed to achieving the highest level of customer satisfaction.

As a company specializing in tungsten carbide parts and materials, we promise to continue dedicating ourselves to the development of technology and services.

We sincerely ask for your continued support and encouragement, and we will strive to become a company that contributes to our customers and society.

Thank you.

-

- Business Type :

- Manufacturer

-

- Main Product :

- tungsten powder, cutting tools

-

- Established :

- 2001-02-16

-

- Total Annual Revenue :

-

- Total Employees :

- 51~100 people

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

-

- Total export revenue (previous year in USD)

-

- Number of foreign trade employees

- 51~100 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

SILVER

SILVER

- KBM corporation Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★